Explosion Protection Systems

Any industrial setting that has volatile dust is at risk for spontaneous explosions. When fine dust particulate becomes airborne, and finds a combustion source, explosions can occur. Industries that require explosion protection and fire suppression equipment include agriculture and grain, chemical processing, and material conveyance. The application specialists at Airpro can help you select the right equipment to prevent explosions and fires caused by combustible dust and gases.

Applications

- Agriculture and Grain

- Chemical Processing

- Plastics and Polymers

- Oil, Gas, and Petroleum

- Metalworking

- Wood Products

- Recycling

- Food Processing

Brands

- IEP Technologies / Hoerbiger

- Hansentek

- Boss Products

- Blender Products

Why Explosion Protection is Needed

Combustible dust and vapors can cause an explosion when all five pieces of the Dust Explosion Pentagon are present. These explosions can be sudden and violent causing loss of life and destruction of the workplace. Certain industries are prone to combustible dust and necessitate a comprehensive explosion prevention plan.

Here are the five components of combustible dust explosions.

- Fuel. Combustible dusts are fuel for combustion. These can include dust from grain, rice, sugar, cornstarch, plastics, wood, coal, and metallic dust.

- Oxygen. Oxygen from the air allows combustion to occur. A sufficent amount of oxygen must be present to support combustion.

- Dispersion. When layers of dust in a facility are kicked up into the air, suspended clouds of combustible dust are present. Concentrated clouds of dust are more likely to combust than dust in a layer.

- Confinement. Suspended dust clouds in a confined space build up pressure, that creates an explosion. When combustible dust ignites without the pressure found in a confined space, it is a flash fire.

- Ignition. This leg of the explosion pentagon is the only one not commonly present. Ignition sources can include open flame, hot surfaces, static or electrical discharges, frictional heat, or heat from mechanical impact.

Preventing Workplace Explosions Through Systems

The National Fire Protection Association (NFPA) has regulatory guidelines governing combustible dust in the workplace. NFPA 652, Standard on the Fundamentals of Combustible Dust (2019), requires that facilities and processes are designed to mitigate the dangerous consequences of fires and explosions that are a hazard of handling combustible dust.

Explosion prevention systems may include some of these components, equipment, and processes.

- Gas and spark detection equipment.

- Explosion vents or flameless vents.

- Dust extraction systems that filter fine combustible dust.

- Fire suppression equipment.

- Fully enclosed pneumatic conveyance systems that reduce combustible particulate.

- Proper ventilation of workplaces, processing areas, and material transport.

- Sensors for detecting issues with grain storage and dust from agricultural products.

- Systems for reducing potential sparks from electro-mechanical or other sources.

- Good housekeeping practices that reduce accumulated dust.

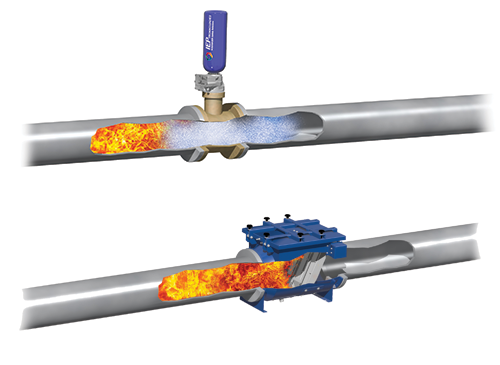

Active and Passive Isolation

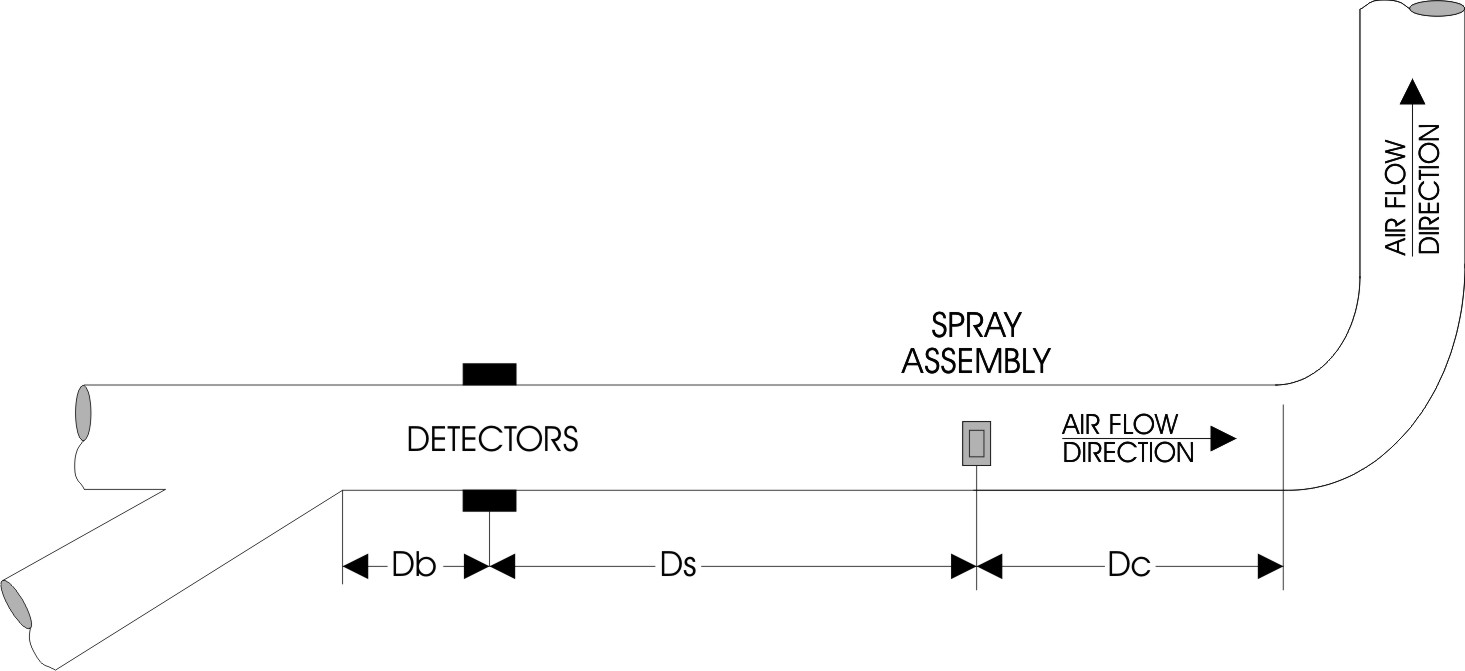

Detect and Extinguish Systems

Explosion Isolation Valve EV-VF VigiFlap

HansenTek Abort Damper

Flameless Explosion Vent

Donaldson Torit Sealed Drum Kit

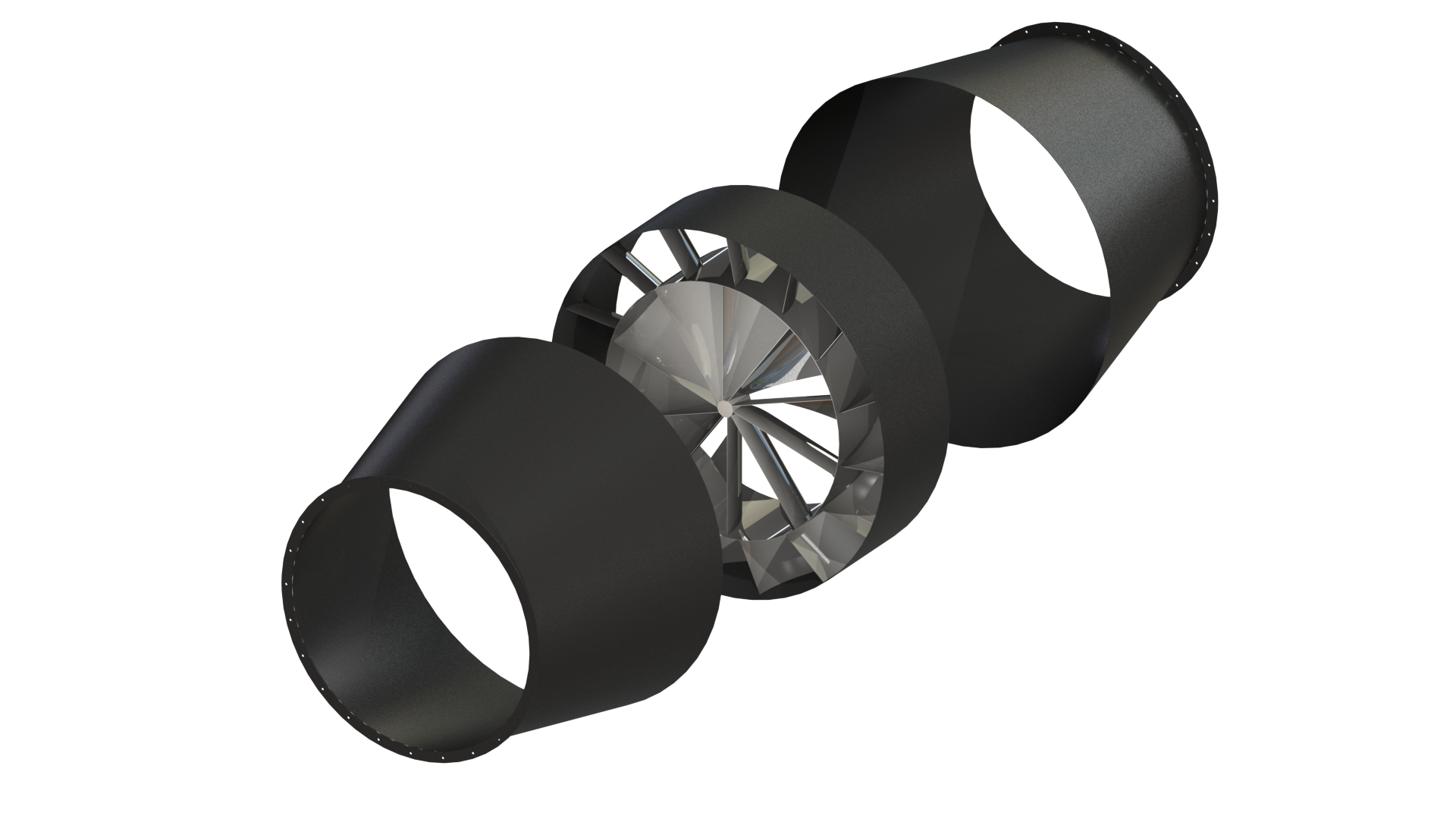

Blender Products Spark Cooler

Don’t See What You’re Looking For?

Other Custom Solutions Are Available

Contact an applications specialist to get help with an air filtration solution for your facility or plant.